|

Three common failure problems of the ME Super come to mind:

1. Over zealous winding

A. Winding too hard, especially at the end of the wind stroke, can

shear off the tab shown below. If this is the problem the wind lever

will move freely until it wedges into the other components under the

frame counter plate.

And… you’ll be in for some serious disassembly.

B. Winding too hard when the wind lock isn’t released will

bend the wind lock catch. You’ll know it is bent if the wind

lever can be wound, then wound again without releasing the shutter.

But luckily it can usually be bent right back in position without

permanent damage.

A properly adjusted wind lock is shown in the released position. If

the tip angles more towards the back of the camera (up in the photo)

or the curved inner part of the catch doesn’t set flush on the

crank cam, it needs rebending.

Holding the wind lock disengaged while winding the camera is

known as “resetting”. Resetting should be the first thing

tried when a camera locks up because it puts everything into a pre shutter

release position. Sometimes holding the mirror in an up (or down) position

while resetting is advantageous.

DO NOT TOUCH THE SILVERED MIRROR SURFACE.

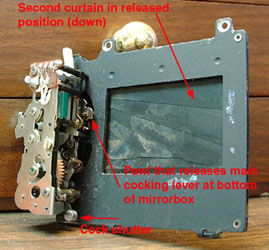

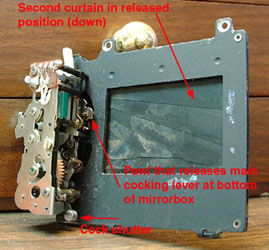

2. The release cycle not completed

—not all the

dominoes fell down.

Drag in the curtain mechanism will cause the curtains to slow down.

When really bad the second curtain may not descend with enough momentum

to trigger the release of the mirror. Cleaning of the shutter and mirror

mechanisms are usually required. But other things may also cause the

problem. For instance a film chip may get into the curtain track. Pushing

the curtain down with the tip of a fingernail may be all that is required

to complete the cycle and allow the mirror to drop.

Whatever you do—DO NOT squirt oil or WD-40 on the blades

or ANYPLACE in the camera for that matter. Very little lube is needed

in a camera.

Many inexperienced tinkerers will increase the curtain tension, (especially

on the easy to access curtain tensioners on cloth style horizontal travel

curtains) but this isn’t the best way to fix the problem. In fact,

it often will cause uneven curtain speeds and therefore uneven frame

exposure. Once the mechanism is cleaned the factory tension setting

usually brings the curtain speeds back up to par.

I have had some luck setting the assembled body with the wind side

down and squirting in some Ronsonol. Only the bottom cover need be removed.

I don’t recommend this as who knows where the dirt and dried lube

may go. Even worse problems might be created. The only real way to fix

slow curtains is to remove the mirrorbox and simply clean out the dirt

and old, dried lubricants with Ronsonol. The shutter assembly itself

can remain in the camera body. Seriously, the mirrorbox isn’t

that hard to remove to do the job right.

3. The camera auto-releasing.

This can be caused by different things, but the most common cause is

probably the main cocking lever not latching. Often one of three things

may cause this.

A. The main cocking lever isn’t being stroked far enough during

cocking because the lever that pushes the main cocking stub has bent

over time. This lever is fairly thin and can bend easily. This lever

is pointed out in a previous photo.

To bend it back in place remove the slide mechanism under the bottom

cover. Only three screws hold it. It comes off cleanly. There are previous

photos showing this mechanism both on and off. The part that usually

bends is the section closest to the stub itself.

B. If the camera auto-releases right side up, try turning it upside

down. If it then winds and releases normally, the spring shown to

the left has fallen off the lever.

This is the lever that the mirror mechanism engages (step 4 in the

photo) to release the first curtain. Without the spring attached the

first curtain will not latch when the camera body is right side up.

This spring is real easy to knock off when reinstalling the mirrorbox.

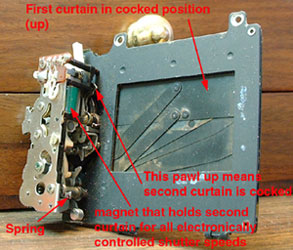

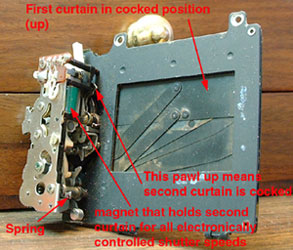

C. If the pawl shown here doesn’t latch when being cocked it

will release the main cocking lever as the wind lever is being returned.

Dirt can cause this but so can a bent slide arm. The slide arm is

the crank arm looking gizmo under the bottom cover. When it is bent

it doesn’t pull the shutter cocking lever far enough to latch

the second curtain.

Also the white plastic levers can stick and prevent the second curtain

from latching. But this isn’t real common.

The green electro-magnet (seen mounted inside the shutter mechanism),

when powered, holds the second curtain until the electronic timer runs

out. All shutter speeds visible in the viewfinder are electronic. Even

when the mode dial is set to manual the speeds are still electronic.

They are all run by the same electronic timer circuit. But in all other

respects the mechanical dominoes fall consecutively.

|